Download Now

24/7 ONLINE SUPPORT

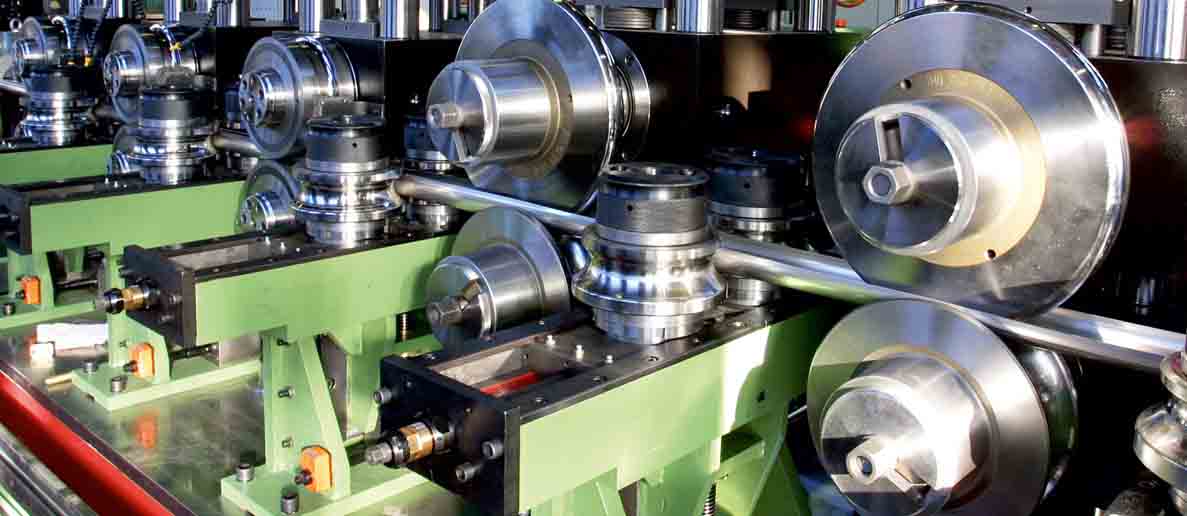

Tube Mill

In 2001, Excel embarked on its commercial journey in the production of Pipes and Tubes, primarily aimed at securing a reliable supply for our renowned Scaffolding and Formwork Manufacturing Division.

Our comprehensive range of steel tubes and pipes adheres to esteemed international standards, including ASTM, BS, JIS, SAE, AISI, and DIN. At Excel, we have fostered a robust local and regional reputation grounded in meticulous engineering, top-tier manufacturing practices, and the procurement of premium raw materials sourced from integrated steel plants spanning the globe. Employing cutting-edge technology, our high-speed pipe manufacturing processes encompass circular, square, and rectangular steel tubes, all executed with utmost precision.

The fabrication of Electric Resistance Welded (ERW) Pipes / Tubes is a seamlessly automated procedure. Hot Rolled Steel Coils are meticulously uncoiled, leveled, and subsequently slit into precise strips. These strips are seamlessly fed into the Forming Mill, where they undergo pipe shaping and formation, culminating in a flawless fusion accomplished by our High-Frequency Induction welder. The resulting welded points exhibit the same unwavering strength as the base metal itself. To achieve superior results, the formed pipes undergo meticulous air and water cooling, culminating in a sequence of accurate sizing, cutting, and straightening processes.

Typical ERW Pipe/Tube Manufacturing Process:

Our manufacturing process generally involves the following stages in a step-by-step procedure.

This production process is steady, continuous, and automatic.

Our Tubes and Pipes are versatile enough to be used in various industries and reasons including Electrical and Gas transmission, Liquid transportation, Oil and gas drilling, Irrigation, Petrochemical piping, pharmaceuticals, Structural, Hydro form, and Mechanical tubing as well as Exhaust pipes.

Quality Assurance

Meticulous quality control here at Excel ensures the highest levels of customer satisfaction. Since we have total control over the entire manufacturing process we are able to monitor every aspect of the completion of each product. We insist on the best, right from the sourcing of raw materials to the presentation and sale of the finished product. A series of uncompromisingly vigorous test are carried out at each stage to ensure meticulous and faultless perfection for our customers.

Inspection, Measuring and Test Equipment

Mechanical Testing

- Universal Testing Machine – 60T capacity

- Brinnell, Rockwell & Vickers Hardness Testing Machine

- Charpy & Izod Impact Testing Machine

Dimension Checking

- Vernier Caliper

- Micrometers

- Steel Tapes

Metrological Testing

- Slip, Ring & Plug Gauges

- Thickness Gauge

- Radius Gauge

- Bevel Protector